Blog – Top 5 Rooftop Hazards and How to Prevent Them

Working at height presents unique challenges that require careful planning and proper safety measures. For construction companies, roofing contractors, and maintenance teams, understanding common rooftop hazards can mean the difference between a successful project and a workplace accident. This guide examines the five most dangerous rooftop hazards and provides practical prevention strategies to keep your team safe and compliant.

Falls remain the leading cause of workplace fatalities in the construction industry. Whether from roof edges, through skylights, or from ladders, these incidents can happen in seconds but have lasting consequences.

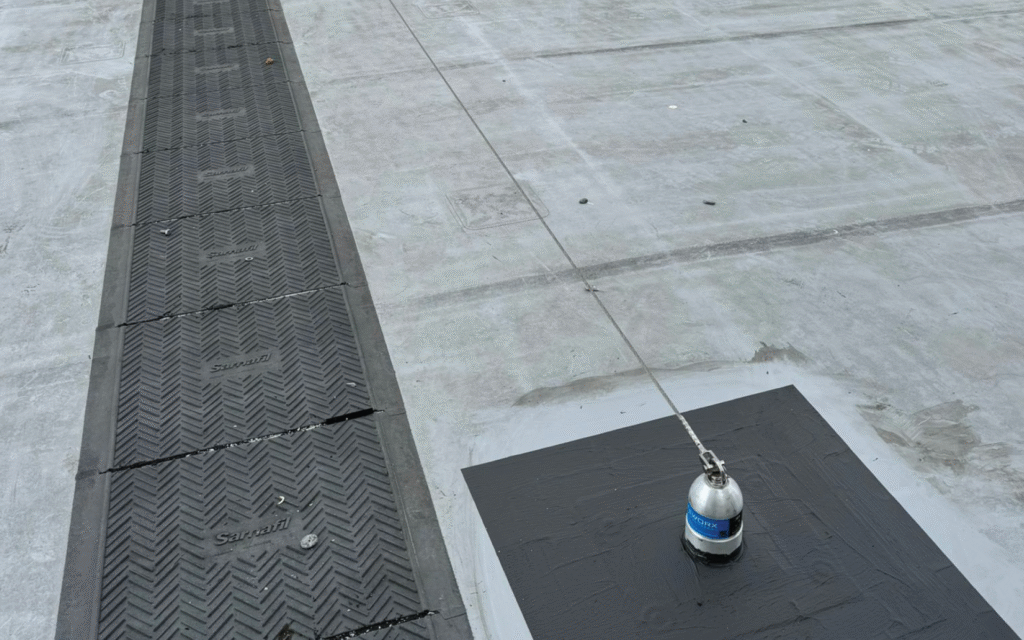

These systems provide continuous protection as workers move across the roof surface. A properly installed cable system allows freedom of movement while maintaining constant connection to a secure anchor point. Modern systems can accommodate multiple workers and adapt to various roof configurations.

Temporary or permanent guardrails create a physical barrier between workers and fall hazards. They require no special training and provide immediate protection for anyone working near roof edges. Guardrails must meet minimum height requirements and withstand specified loads to ensure regulatory compliance.

When other protective measures aren’t feasible, personal fall arrest equipment provides individual protection. This includes full-body harnesses, lanyards, and secure anchor points. Regular inspection and proper training are essential for system effectiveness.

Skylights pose a significant risk because they may appear solid from above but cannot support a person’s weight. Weather conditions can make skylights especially difficult to identify, leading to accidental falls through these openings.

Purpose-built skylight covers distribute weight across the roof structure rather than the skylight itself. These covers should be clearly marked and secured to prevent displacement. Quality covers can support multiple workers and resist weather conditions.

Installing permanent screens below skylights provides ongoing protection without requiring covers for each access. This solution works well for facilities with regular maintenance requirements.

Creating marked exclusion zones around skylights alerts workers to potential hazards. Combine this approach with physical barriers for maximum effectiveness.

Some roofing materials cannot support concentrated loads or may deteriorate over time. Walking on unstable surfaces can lead to falls through the roof or structural damage.

Installing walkways creates safe paths across fragile roof surfaces. These systems distribute weight evenly and provide secure footing regardless of underlying roof conditions. Walkways should connect all frequently accessed areas including equipment and maintenance points.

Conduct thorough structural assessments before beginning work. This includes evaluating the roof’s load-bearing capacity and identifying areas of concern. Documentation ensures all team members understand surface limitations

Proper footwear with adequate grip reduces slip risks on various roof surfaces. Consider weather conditions and surface materials when selecting appropriate footwear for your team.

Weather conditions can rapidly change rooftop safety levels. Rain, wind, ice, and extreme temperatures all create additional risks that require specific precautions.

Implement systems to monitor weather conditions and establish clear protocols for suspending work when conditions become unsafe. This includes wind speed limits, precipitation guidelines, and temperature considerations.

Apply anti-slip treatments to frequently used areas. These treatments improve traction in wet conditions and reduce slip hazards year-round.

Temporary shelter systems protect workers from weather while maintaining access to work areas. These systems can be particularly valuable during extended projects in challenging climates.

Power tools, extension leads, and equipment can create trip hazards or cause injuries if not properly managed. Dropped tools also pose risks to workers below.

Secure all tools and equipment to prevent drops. Tool tethering systems keep equipment connected to workers or secure anchor points throughout use.

Maintain clean, organised work areas with designated storage for tools and materials. This reduces trip hazards and improves overall site safety.

Use appropriate electrical protection including RCD units and weatherproof connections. Ensure all electrical equipment is suitable for outdoor use and regularly inspected.

Preventing rooftop hazards requires ongoing commitment and proper systems. By implementing appropriate safety measures and maintaining them correctly, you can significantly reduce workplace risks while ensuring regulatory compliance.

The key to successful rooftop safety lies in understanding your specific hazards and implementing tailored solutions. Whether you need cable-based fall protection, skylight covers, or comprehensive walkway systems, investing in proper safety measures protects your team and your business.

For expert guidance on implementing these safety solutions or to discuss your specific rooftop safety requirements, contact our team for a comprehensive consultation. We can help you develop customised safety systems that meet your project needs and ensure compliance with current regulations.